Throughout the long journey of human exploration of the Earth's treasures, prospecting technology has always played a crucial role. From ancient geological exploration to today's high-tech means, every technological innovation has greatly promoted the discovery and development of mineral resources. Hyperspectral technology, as a cutting-edge technology that has rapidly emerged in recent years, is bringing unprecedented changes to the field of mineral exploration with its unique advantages. It is like a bright "searchlight", illuminating the path of seeking underground treasures.

Hyperspectral technology is essentially a technique based on spectral analysis. We know that each substance, when exposed to light of different wavelengths, will absorb, reflect or emit specific spectral characteristics, which are as unique as the "fingerprints" of the substance. Hyperspectral technology can accurately identify the composition and properties of substances by obtaining spectral information of objects in multiple continuous bands. In the field of mineral exploration, the application of this technology can be described as thriving.

Traditional mineral exploration methods often rely on on-site investigations by geological personnel, sampling analysis, and some physical detection means, such as seismic exploration and magnetic exploration. Although these methods can provide valuable information to a certain extent, they also have many limitations. For instance, field investigations consume a great deal of human and material resources and are restricted by natural conditions such as terrain and climate. Sampling analysis requires the destruction of the rock structure on the surface or underground, and can only obtain local sample information. However, physical detection methods are rather difficult for some ore bodies deeply buried underground, especially those whose physical properties are not much different from those of the surrounding rocks. The emergence of hyperspectral technology has effectively made up for these deficiencies.

Hyperspectral prospecting equipment can rapidly scan large areas from the air or the ground to obtain spectral data of surface and shallow rocks. By analyzing and processing these data, scientists can identify the "spectral fingerprints" of potential ore bodies just like reading pa sswords. For instance, the spectral reflectance of certain metallic minerals varies significantly in specific bands. Through hyperspectral imaging, these subtle differences can be clearly captured and presented in different colors or brightness on the image, thereby providing geologists with key information such as the distribution range, scale, and general mineral composition of the ore body.

In addition, hyperspectral technology also has the advantages of non-contact and non-destructive testing. This means that during the exploration process, there is no need for large-scale destruction or sampling of the surface, which not only saves time and costs but also reduces the impact on the natural environment. Moreover, with the continuous advancement of technology, the resolution of hyperspectral equipment is getting higher and higher, and the details of ore bodies it can detect are also becoming increasingly rich. It can not only discover large ore bodies, but also effectively identify and locate some small and scattered ore veins, greatly improving the efficiency and accuracy of mineral resource exploration.

In practical applications, hyperspectral technology has achieved remarkable results. In some remote mountainous areas and complex terrain regions where traditional exploration methods are difficult to apply, hyperspectral technology, with its flexible detection approach, has successfully discovered multiple potential mineral resources. Through the re-exploration of historical mining areas, hyperspectral technology has also helped people discover new extensions of ore bodies, providing a strong basis for the secondary development of old mining areas. At the same time, it also provides new ideas and methods for the exploration of some emerging mineral resource development fields, such as rare earth mines and rare metal mines.

However, the application of hyperspectral technology in mineral exploration also faces some challenges. Due to the complexity and diversity of spectral data, data processing and analysis require professional technical talents and advanced algorithm support. In addition, the cost of hyperspectral equipment is relatively high, which to some extent limits its large-scale popularization and application. However, with the maturation of technology and the reduction of costs, these problems are expected to be gradually solved.

VNIR and SWIR

VNIR sensitive minerals iron oxides, hydroxides (iron sheets, goethite, olivine, pyroxene)

Functions metals related to transition: iron, manganese and chromium

SWIR sensitive minerals Silicates, sulfates, hydroxides (clay minerals, potassium feldspar, orthoclase, amphibole, mica bound with Al, Fe and Mg hydroxyl)

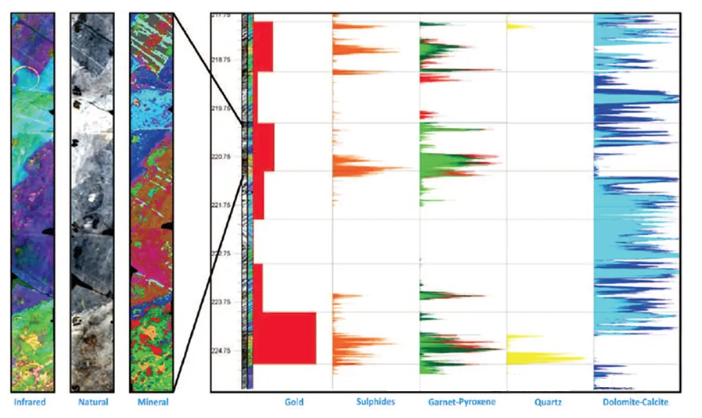

The purpose of infrared natural mineral exploration, gold sulfides, garnets, pyroxenes, quartz, dolomite, calcite, iron oxide minerals and rare earth element mineral exploration is to find economically feasible deposits.

Short-waveinfrared (Shortwave infrared imaging;1300- 2500nm) wavelength region data is typically used for this purpose, but the near-infrared wavelength region also provides two key geological applications: → detection of oxidized iron minerals → detection of rare earth elements Oxidized iron minerals are crucial for mineral exploration because they are often the only visible clues to underlying deposits.

Oxidized iron minerals have characteristic spectral features in the 800 ~ 1000 nm band, which can be used for remote sensing identification.

Oxidized iron concentration is related to specific rock types ("host rocks"), and host rocks are sometimes associated with potential deposits.

Recent research indicates that hyperspectral imaging can classify oxidized iron concentration based on its host rock matrix, thereby increasing the potential for detecting rock outcrops most likely to be associated with deposits.

Rare earth elements (REEs) are a group of metal elements that are indispensable in the manufacture of high-tech products (such as consumer electronics).

These elements are found in certain minerals, and many of them can be identified due to their key spectral features in the near-infrared wavelength region.

Remote sensing provides a potentially cost-saving tool for exploring economically enriched deposits of rare earth minerals.

MWIR mid-wave infrared

Sensitive Minerals in MWIR Carbonates, silicates, phosphates, sulfates, carbonates (quartz, talc, phosphate rock, gypsum) are related to the Si-O bond

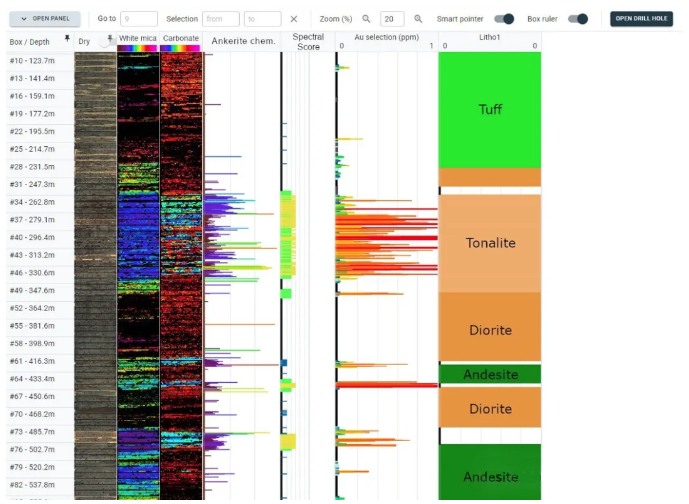

Utilizing mid-wave infrared hyperspectral imaging to create carbonate alteration maps. Mid-wave infrared (MWIR) is rarely used in core scanning, but it is very effective at detecting even low concentrations of carbonates. Calcite (red) and ankerite or siderite (blue) highlight the alteration around orogenic gold systems, showing a strong correlation with gold content. When the chemical composition of muscovite (e.g., muscovite and polythermal muscovite) gives unclear responses in different lithologies, this method provides valuable insights

LWIR

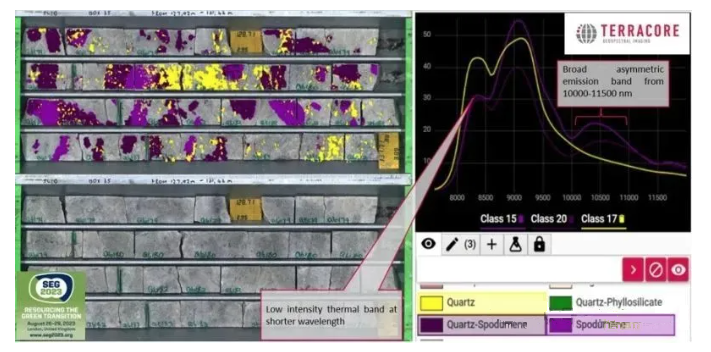

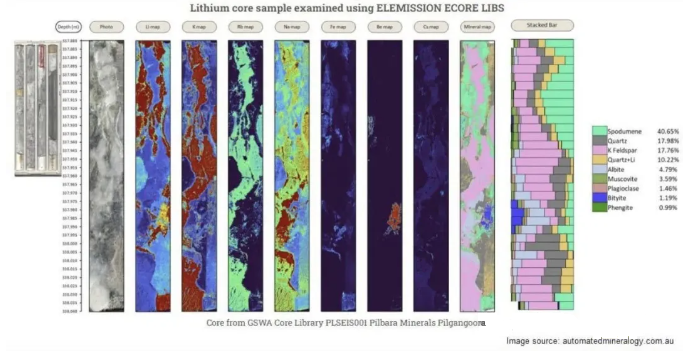

In the following examples, using long-wave infrared, geologists can identify spodumene, and even sort out a mixture of quartz and spodumene from this pegmatite.

Here is a small table summarizing what hyperspectral technology can measure regarding minerals

The emergence of hyperspectral technology in mineral exploration is undoubtedly a major breakthrough in the field of geological surveying. With its characteristics of efficiency, precision, and environmental friendliness, it has opened up a completely new path for humans to search for underground treasures. As the technology continues to develop and improve, we have every reason to believe that hyperspectral technology will play an even more important role in future mineral exploration, making greater contributions to human resource development and economic growth.

Related products: please click here