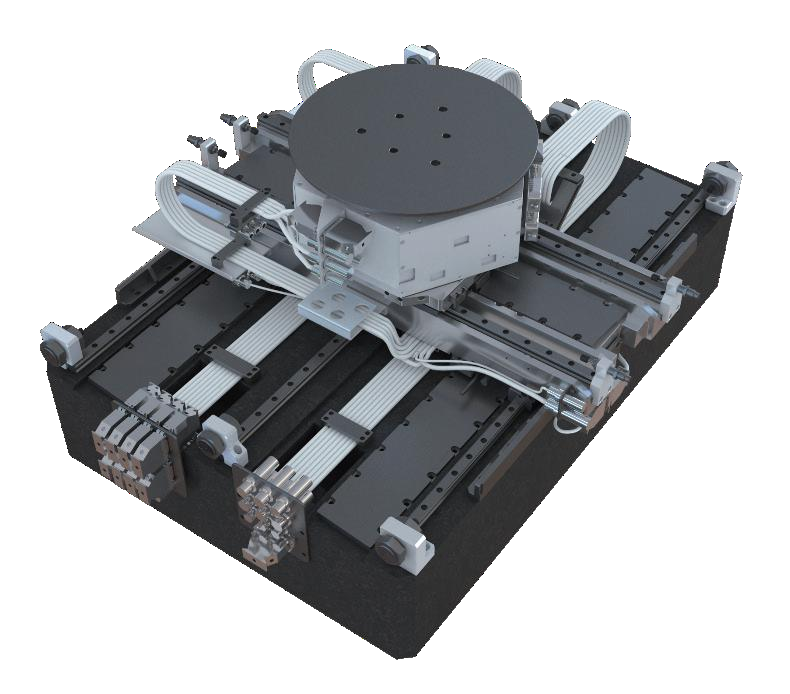

| The M6S800-00 series stacked precision six dimensional motion table from Goptica adopts the concepts of modularity, ultra-thin design, and orthogonal design. The Z3T standard module is integrated on top of the XYY stacked horizontal motion module, which can achieve high-precision and high stiffness motion in 6 degrees of freedom in X, Y, Rx, Ry, T, and Z axes. The Z3T standard module adopts compact design technology, integrating Z, Rx, Ry, and T axes, and has excellent positioning accuracy, flatness, straightness, rigidity, and repeatability accuracy. The unique maglev gravity compensation technology is adopted vertically, which reduces the load on the vertical voice coil motor and greatly improves the vertical motion performance and service life. The XYY stacked horizontal motion module adopts an integrated and orthogonal design concept, with a compact and flat contour size, which can achieve high-precision and high stiffness linear motion with 2 degrees of freedom in the horizontal X/Y axis. It can be widely used in wafer production control applications, such as thin film measurement, critical dimension inspection, as well as wafer marking and laser annealing, especially suitable for flip chip packaging on specific large panels/substrates.

Product manual:

|

- Stacked 7-axis platform, orthogonal design - Global flatness and straightness reach micrometer level - X/Y axis High stiffness and high-precision guide rail design Consistency design of cable disturbance force

| - Z3T axis Vertical magnetic levitation gravity compensation can achieve high positioning accuracy Flexible Guided Design Vertical incremental grating, capable of achieving a maximum resolution of 1.2 nanometers Ultra thin and lightweight design Maximum support speed 240rpm

|